IFT@JKPG -Innovative Foundry Technology

Facts

Academic centre: Tekniska Högskolan i Jönköping

Partner companies: Scania CV AB External link, opens in new window., SinterCast AB External link, opens in new window., Volvo Group Technology AB External link, opens in new window., SKF Mekan AB External link, opens in new window., Bruzaholms Bruk AB External link, opens in new window.

Financier: KK-stiftelsen, SinterCast AB, AB Bruzaholms Bruz, Volvo, SKF, Scania

Project duration: Mar. 2022- Feb. 2029

Research group

Attila Diószegi (Project Leader),

Björn Domeij External link, opens in new window.

Lucian Vasile Diaconu

Vasilios Fourlakidis

Ilia Belov External link, opens in new window.

Taishi Matsushita

Dinesh Sundaram

Ricardo Queirós

Claudia Guedes

Helena Stolt Olson

Scientific Advisory Board

Professor Doru Stefanescu, Ohio State University, US

Professor Roberto Boeri, University of Mar del Plata, Argentina

Professor Jacque Lacaze, CIRIMAT Toulouse, France

IFT@JKPG is a research profile at Jönköping University aimed to focus on the materials and manufacturing process of cast iron in collaboration with leading cast iron developer and producer companies where state-of-the-art methods and instruments are used to solve complex industry-related research questions extending the knowledge frontier in materials and manufacturing technologies. The research profile becomes a strategic partner for the collaborating enterprises, who invest more than 5 billion SEK in new cast iron Foundries in Sweden.

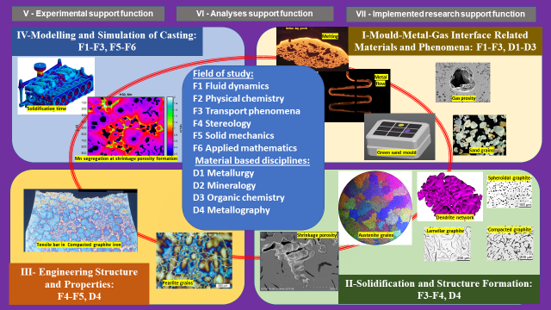

Phenomena observed in melting and solidification of casting are complex and demand a combined multidisciplinary expertise in various fields of study and other adjacent disciplines. The project profile includes four research areas (see figure below): Mould-Metal-Gas Interface Related Materials and Phenomena (I), Solidification and Structure Formation (II), Engineering Structure and Properties (III), Modelling & Simulation of Casting (IV) supplemented with three support functions in Laboratory experiments (V), Fundamental disciplines (VI), and Industrially Implemented Research (VII).

Purpose

Based on societal, industrial, and academic needs the objective of the present research profile is to line up a transdisciplinary research activity and become the first-choice research partner in the world. Thereby the research profile implementation will enable a lean and sustainable design and production of cast iron components, supported by a progressive research environment driven by top-ranked scientists in their research area.

A part of the objective is to reach a critical mass of knowledge and competence, enabling the existence of the research profile long after the official project period.

Expected results

The present project supports cast component users, producers, and suppliers to the casting production industry. The knowledge coproduction model applied in the projects is expected to promote the innovation process at cooperating partners including both large and small industrial companies and academia. Production processes and implementation of cast components in final products are expected to become lean and sustainable with respect to the environmental challenges. Project results will be distributed to industry both domestically and internationally.

Financier

Do you want to know more about the project?

- Professor Foundry Technology

- School of Engineering

- attila.dioszegi@ju.se

- +46 36-10 1656

Are you interested in future collaborations?

- External Relations Manager

- School of Engineering

- linda.bergqvist@ju.se

- +46 36-10 1074

ju.se/center/spark

%20morkbla-logo-staende-eng.png)